Verrerie Dumas, Noizay

Established in the Loire Valley near Amboise, Verrerie Dumas is specialized for more than 70 years in scientific glassblowing for research, oenology, chemistry, civil engineering, petrochemicals, health or agri-food industry. From custom parts to small or medium-volume production, our products are mainly manufactured by glassblowing using blowtorch technique and produced in high quality borosilicate, sodalime or quartz glass tubes.

The company is illustrated by its production capacity, the large size of its workshop, the expertise in glass technics (volumetry, engraving, cold working, gauging, thermometry, etc.) and by its Engineering and Development Office which has always been innovative in the design of tailor-made solutions adapted to the very specific requirements of customers.

Traditionally specialized in the agro-food industry, Verrerie Dumas is well-known for its butyrometers in dairy industries. It is also a reference in the oenological analysis laboratories, with a wide range of alcoholmeters, hydrometers, analysis instruments, as well as chemical laboratories for its custom-made products ...

Being a reference for laboratories and endowed with a strong industrial, technical and human heritage, the company wanted to diversify. So, it moves towards an artistic activity by creating the brand VERART.

Thanks to a team of 20 people, including 8 glassblowers, we are able to respond to any request, whether it comes from professionals or individuals.

Quality procedure

The company adopted a quality approach very early on and obtained the French Norm (NF) for some of its products. At all stages of production, operators perform a qualitative and quantitative self-check, then validated by an independent quality manager. State control is also carried out on certain products by the LNE (National Testing Laboratory).

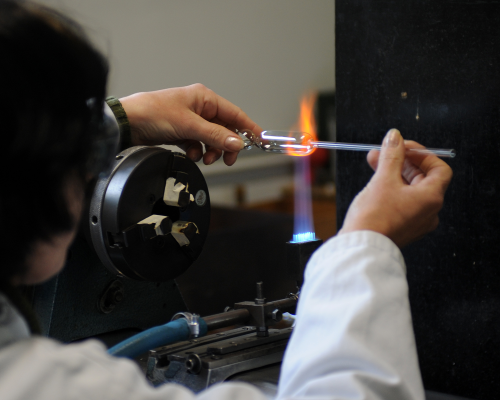

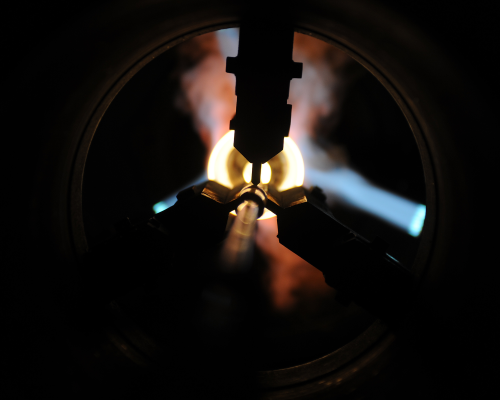

Glassblowing & Borosilicate

The craftsman creates pieces by blowing, modeling, or stretching tubes or rods of glass 1m50 long and of different diameters. The heat of the flame of the torch makes it possible to obtain a fusion with more than 1200 degrees. Before the manufacturing stage, the blower reads the plans and analyzes the method to be followed for each piece. Manufacturing is divided into three stages: calibration, shaping and assembly. For shaping, the blower can also use different tools in metal or graphite, such as a pliers, a knife or a reamer. The glass is turned by hand with a regular gesture or, for larger pieces, using a lathe.

We make systematic quality control procedures (internal checks and/or state control procedures) throughout the entire production process of our products.

Borosilicate glass, very resistant to thermal shock, tolerates temperatures of 400 ° C, if a slow and gradual cooling process is observed. Borosilicate glass is also very resistant to most chemicals, with the exception of hydrofluoric acid, phosphoric acid and alkaline solutions which attack glass.

The brands of Verrerie Dumas :

• VEREXA is the brand for laboratory glassware and oenological analysis instruments.

• VERPRECIS is the brand for calibrated and dairy items.

• VERART is the brand of Verrerie Dumas ' decoration and design activity.