Beyond glassblowing, our expertise allows us to use all glassworking techniques with precision and quality. To satisfy the needs of our customers, we offer a technical and commercial response that is always adapted, even when it is to be invented or created.

Repair

Repair of parts to increase their lifetime. According to your needs, the repair can be done identically, or introduce some changes to improve their use.

Metrology

In partnership with the company E.R.IN, Study and Research in Industry, we provide a metrology service. We thus strengthen our expertise in the calibration, control, verification and maintenance of your instruments at any time. It is indeed essential for us to ensure control of your instruments and to guarantee you a very high quality service throughout the life of the instrument.

Traditional engraving

Targeted attack on a glass part with hydrofluoric acid. The engraving is tailor-made, according to your needs and specifications. In particular, we engrave scales on volumetric parts.

Sanding

Glass sandblasting consists of roughening the surface of the glass by spraying sand at high pressure in a closed cabin.

Coating

Application of different coatings (inactinic, silicone, surlyn, silver plating or PTFE) to adapt your parts to their conditions of use.

Diamond wheel cutting

Cutting with a diamond disc.

Glass - metal welding

Realization of glass chain to approximate the coefficient of dilatation of the metal used.

Work with a vacuum system

Manufacture of calibrated tubes

Chromography

Customisation with logo.

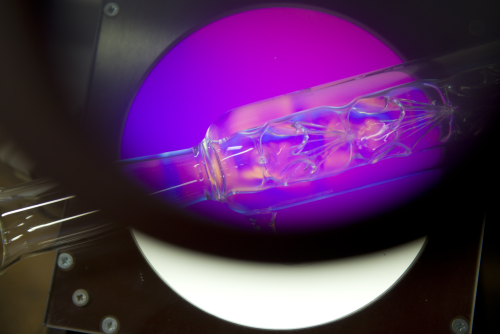

Inactinic glassware

Amber glass, UV protection. To protect the contents of photosensitive products from rays causing photochemical reactions.